Product Details

| Precision: | High Precision | Certification: | CE, ISO 9001: 2000 |

| Condition: | New | Technical: | Cold Saw |

| Cutting Way: | Wet Cutting | Motion: | Pneumatic |

| Color: | Standard or Customized | Voltage: | Standard or Customized |

| Cooling: | Water Cooling | Applicable Material: | S. S., M. S., Copper, Aluminium, Alloy, Galvanized |

| Applicable Pipe Shape: | Round, Rectangle, Square, Oval, Solid Bar, Profile | Angle Cutting: | Yes |

| Pipe Loading: | Manual | Saw Blade Type: | HSS Blade |

| Advantage: | Economical | Trademark: | Beyong |

| Transport Package: | Wooden Case | Specification: | 700X1000X1300 |

| Origin: | China | HS Code: | 8461500090 |

Product Description

PECIFICATION

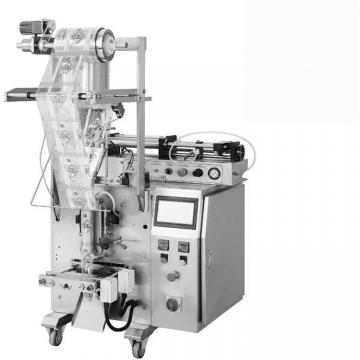

| Packing speed | 5-60bag/min |

| Bag-making size | (L)50-300mm(W)60-200mm |

| Filling range | 150-1300ml |

| Max packing film width | 40mm |

| Film thickness | 0.04-0.08mm |

| Air consumption | 200L/min,0.7*10Pa |

| Total power/voltage | 2.2KW/220V 50-60Hz |

Function

1.Working processing:Put prepared production into the chain bucket manually-conveying-coding(optional)-bag making-filling-gas injetction/exhaust(optional)-sealing-counting.

2. Computer/PLC control,photoelectric tracking,gas fault display system,easy to operate and maintain.

3. The prawn cracker can make hole pinching blade,linked bags device or easy tear notch device and so on according to customer's request.

4. Machine body and all product touching pats are made of stainless steel(bucket material:food grade plastic/stainless steel).

5. Optional languages screen display, easy and simple operation.

6. Bag-making with precise technology enable the error less than ±o.5um.

7. High-sensitivity photoelectric color tracing and digital input of cutting position get more accuracy.

8. Intelligent temperature controller and excellent heat balance make all kinds of packaging materials possible with good performance, low noise, clear cutting pattern and strong seal ability.

9. Packaging speed and length of bags can be set to some extent without parts changing.

Our Services

1: Machine inspection,installation and operation training conducted.

2: Wipes production experience provides.

3: Machine settled for standard plywood case packaging.

4:Balance received and delivery machine.

5: Machine transportation.

6: Long-distance guidance for installation and operation or engineer available for oversea.

7: Life-long machine maintenance service and warranty.

High Efficiency Electric Pipe Saw Cutting Metal Circular Tube Cut off Machine

High Efficiency Electric Pipe Saw Cutting Metal Circular Tube Cut off Machine Automatic Feeding Tube Pipe Cold Saw Machine (MC-400CNC-ML)

Automatic Feeding Tube Pipe Cold Saw Machine (MC-400CNC-ML) Round Pipe Bar Cutting Metal Cutter Tool, Aluminum Profile Circle Cutting Saw Machine

Round Pipe Bar Cutting Metal Cutter Tool, Aluminum Profile Circle Cutting Saw Machine Circular Cold Saw Machine for Cutting Metal Pipe

Circular Cold Saw Machine for Cutting Metal Pipe Automatic Supari Energy Ball Legume Packing Packaging Machine

Automatic Supari Energy Ball Legume Packing Packaging Machine