Product Details

| Power Source: | Hydraulic | Layout: | Horizontal |

| Technical: | Cold Saw | Cutting Way: | Wet Cutting |

| Motion: | Hydraulic | Color: | Standard or Customized |

| Voltage: | Standard or Customized | Cooling: | Water Cooling |

| Applicable Material: | S. S., M. S., Copper, Aluminium, Alloy, Galvanized | Applicable Pipe Shape: | Round, Rectangle, Square, Oval, Solid Bar, Profile |

| Angle Cutting: | Yes | Pipe Loading: | Manual |

| Saw Blade Type: | HSS Blade | Advantage: | Economical |

| Cutting Efffect: | No Burr | Phase: | 3 Phase |

| Clamp Mold: | Standard or Customized | Trademark: | BEYOUNG |

| Transport Package: | Wooden Case | Specification: | 750X1200X1500 |

| Origin: | China | HS Code: | 8461500090 |

Product Description

Description

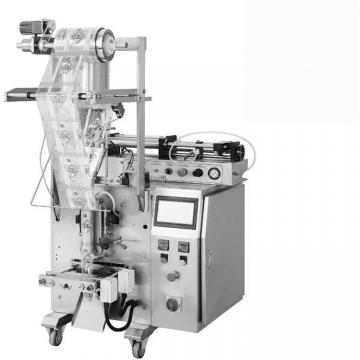

This machine uses the stepper motor control technology and electronic weighing technology, chip control, and it has the functions of auto-quantitative, automatically filling, automatically correcting errors, the counting, cleaning, etc. It is the ideal packing equipment for pesticides, veterinary drugs, chemicals, additives, flour, milk, detergent powder, salt, drinks, sugar, monosodium glutamate, condiments(such as spicy fresh), natural flavourings (such as 13 aromatic), enzymes, feed and other powder (powders and ultrafine powder) material.

Features

1.The machine can automatically complete the products measuring, conveying and feeding, filling and bag forming, date code printing, bag sealing and cutting.

2. Servo-motor driven, twin belt bag pulling system.

3. High sensitive fiber optic photo sensor can automatically trace color mark accurately.

4. PLC control system combined with touch screen, can easily set can change the packing parameters. Daily production output and self-diagnostic machine error can be viewed directly from the screen.

5.PID temperature controller monitors heat sealing temperature within ±1.

6. Automatic edge position control assures consistent film alignment during production to produce uniform bag quality.

Our Services

1.International high quality certification product chain

2.Manufacturer, more reasonable price

3.Solid technical support and after-sales service

4.Uphold the principle of “Customer Supreme”( Balance payment after equipments run normally)

5.Exports to more than 20 countries and regions, good customers feedback

One-stop service, customized exclusive project feasibility report

High Efficiency Electric Pipe Saw Cutting Metal Circular Tube Cut off Machine

High Efficiency Electric Pipe Saw Cutting Metal Circular Tube Cut off Machine Automatic Feeding Tube Pipe Cold Saw Machine (MC-400CNC-ML)

Automatic Feeding Tube Pipe Cold Saw Machine (MC-400CNC-ML) Round Pipe Bar Cutting Metal Cutter Tool, Aluminum Profile Circle Cutting Saw Machine

Round Pipe Bar Cutting Metal Cutter Tool, Aluminum Profile Circle Cutting Saw Machine Circular Cold Saw Machine for Cutting Metal Pipe

Circular Cold Saw Machine for Cutting Metal Pipe Automatic Supari Energy Ball Legume Packing Packaging Machine

Automatic Supari Energy Ball Legume Packing Packaging Machine